ENG

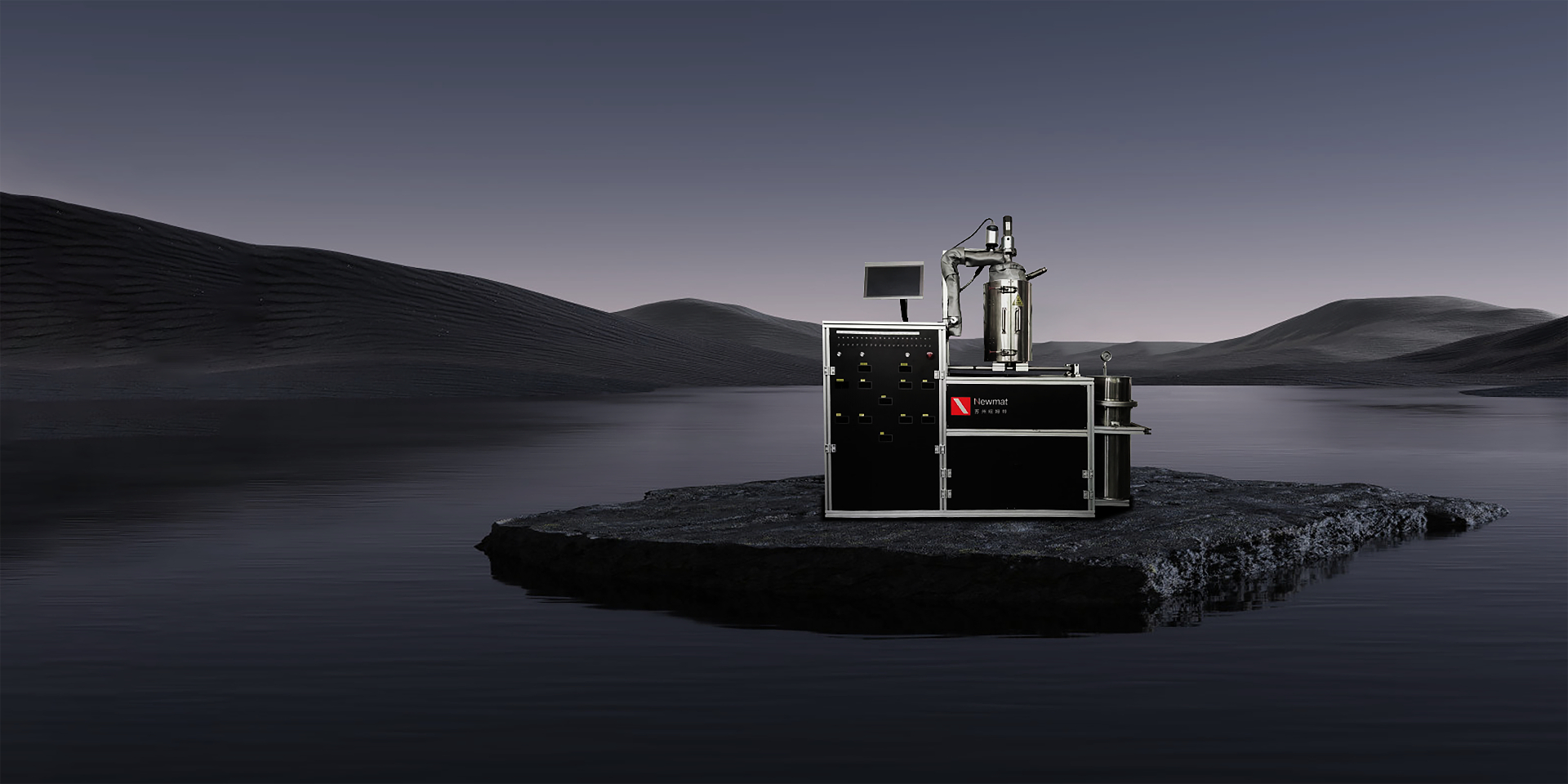

FB-ALD is jointly developed with the national special team and is based on a new deposition method developed on the basis of Chemical Vapor Deposition (CVD), where the deposit is deposited on the surface of the substrate in the form of a single layer of atoms. Because FB-ALD can realize uniform deposition with atomic-level precision, it is especially suitable for deposition processes with high depth-to-width ratios.FB-ALD technology has been commonly used in advanced manufacturing industries such as semiconductors and photovoltaics, but the traditional FB-ALD process is only applicable to the deposition process of sheet materials.