ENG

One of the ways for car companies to increase the range of pure electric vehicles is to improve the battery materials so that the same volume and weight of the battery can carry more energy, and silicon anode with a theoretical energy density of 4200mAh/g is considered to be the most effective and feasible material to improve the performance of the battery. According to incomplete statistics, the global silicon-based negative electrode material market sales amounted to $433 million in 2022, and the Chinese region is the largest consumer market, with China's silicon-based negative electrode material market reaching $134 million in 2022.

As a new type of battery anode material, silicon-carbon anode attracts more and more car companies because of its unique advantages and potential. in mid-December, Azalea electric car completed the 1,000-kilometer range challenge, which injected a “cardiotonic agent” for the tram to get rid of range anxiety. The test car is equipped with the 150kWh battery pack released by Azalea, which has three major technical highlights: semi-solid electrolyte, silicon carbon anode and high nickel anode.

Not only that, domestic anode producers are continuing to expand investment in silicon carbon anode, Betray, Sugo, PuTaiLai, Tianmu Pilot, ZhengTuo Energy and other enterprises can realize mass production. Among them, Betray silicon carbon anode supplies Panasonic power battery and enters Tesla industry chain. Battery companies such as Ningde Times, BYD, Guoxuan Gaoke, Lixin, and BAK are actively laying out silicon carbon anode materials. The models of many car companies, such as EAN, Tesla, Azure, ZhiGi, Mercedes-Benz, etc., have begun to start carrying silicon-carbon negative electrode power batteries.

There are two fundamental reasons for the hot market of silicon-carbon anode material application, one is the urgent demand for high-capacity batteries in the downstream, and the other is the breakthrough of upstream silicon-carbon anode technology. The downstream market is in urgent need of high-magnification, high-capacity and high-safety power batteries to solve the growing mileage anxiety. However, the current graphite anode is approaching its theoretical energy density limit, and it is difficult to make new breakthroughs. Silicon-based anode has the advantages of high theoretical specific capacity, low cost, and environmental friendliness, etc. Compared with graphite anode, it has better fast-charging performance and better safety performance, which makes it the optimal option for next-generation battery materials.

Porous Silicon-Carbon Key Applications and Research Progress>>>

Silicon-carbon negative electrode is a major branch of silicon-based negative electrode, which has the advantages of good stability, small volume change and excellent conductivity. However, silicon-carbon anode also suffers from serious volume expansion effect, poor cycle life and other shortcomings.

Porous carbon materials with high specific surface area, good electrical conductivity, and good mechanical stability are ideal materials to improve the defects of silicon-carbon anode. In terms of technology, the breakthrough progress of the new generation of CVD silicon-carbon anode technology route makes the performance of silicon-carbon anode materials realize a “qualitative leap”.

『CVD method of silicon and carbon anode preparation: the core is silicon storage through porous carbon skeleton. Firstly, carbon particles with porous structure are manufactured by using polymer materials, and then silane gas is delivered to the pores of porous carbon particles, and the gas is precipitated into silicon nanoparticles by high-temperature pyrolysis.』

(1)Increase silicon-carbon negative electrode capacity:The porous treatment of silicon particles increases the specific surface area, which enhances the transfer rate of electrons and ions and enhances the electrical conductivity of the material. It also accommodates the effective expansion of silicon during cycling and avoids crushing of silicon particles due to mutual extrusion during volume expansion.

(2)Improved battery cycle stability:Benefiting from the advantages of porous carbon structure, its electrodes have a very stable structure during the cycling process. In addition, in the chemical vapor deposition (CVD) method in the preparation process, because of its optimized process for the structural design of the material, it usually has a high first-time charging and discharging efficiency and good cycling stability.

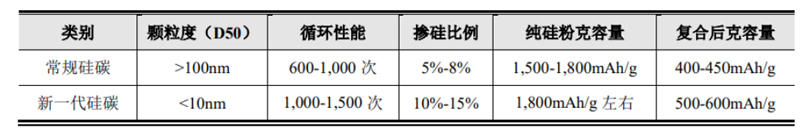

Performance Comparison of Silicon-Carbon Anode by CVD Method and Conventional Silicon-Carbon

Photo credit: Powder Circle

(3)Optimizing Silicon-Carbon Composites:Porous carbon and silicon particles form a composite structure that optimizes material properties. This composite structure not only increases the utilization of silicon, but also improves the overall performance of the cell.

Driven by this technology, downstream battery suppliers and automobile enterprises have great interest in porous silicon carbon materials, and silicon-based anode accelerates the penetration in the field of power batteries, and is even expected to surpass the existing mainstream silicon-oxygen and traditional silicon-carbon routes. According to GGII incomplete statistics, since 2023, the layout of porous silicon carbon enterprises more than 40, porous silicon carbon theoretical monthly production capacity of 750 kg / month, excluding the defective rate of production capacity of about 500 kg / month. Some manufacturers to achieve monthly production capacity broken “tons”, downstream battery manufacturers monthly procurement volume of hundreds of kilograms.

Porous Silicon-Carbon Industrialization Difficulties>>>

Nowadays, the industry usually refers to the vapor-deposited silicon-carbon anode as the technology route originated from the U.S. company Group14, which announced in April 2021 that its silicon-carbon composite anode material products began to be commercially produced. But to this day, the company has not been able to achieve large-scale 100-ton mass production. It can be seen that there are still many difficulties to be solved in porous silicon carbon technology, mainly in the vapor deposition process, equipment, porous carbon selection and preparation.

(1)Vapor Deposition Processes and Deposition Equipment

Uneven gas-phase deposition and imperfect coating will lead to poor performance of rotary kiln equipment, rotary kiln silane utilization rate is reduced, which in turn affects the cost of its mass production of silica-carbon products increased, while the fluidized bed, although there is no need to worry about the problem of uneven deposition and low silane utilization rate, but the equipment's airtightness, air pressure has high requirements to meet the small particles of gaseous coating, facing the difficulty to realize the difficulties in the amplification of mass production. How to develop deposition equipment with good deposition effect, high silane utilization rate, and large-scale, continuous production is one of the industrialization difficulties faced by deposition equipment. In addition, to achieve mass production of deposition process consistency requirements, such as hundred kilograms of mixing, chamber temperature partition, chamber partial pressure, residence time and so on.

(2)Selection and preparation of porous carbon

The carbon skeleton directly determines the mass production capability of the product. Different porous carbon needs to be matched with different graphite in order to show good performance at the core end. Secondly, in different scenarios, the pore size, pore volume and porosity requirements of carbon skeleton are different, and the performance varies greatly, which requires more specialized R&D personnel to complete the development. In addition, the product testing program is quite important, which is related to the accuracy and efficiency of product development.

New energy and new materials related exhibitions

“2024 China (Jiangxi) New Material Industry Chain Conference and Exhibition” will be held from March 15 to 17, 2024 in Nanchang. The investment and exhibition work of the conference has been fully launched, high-quality booths are waiting, welcome to join, seize the business opportunities!

Welcome to register by scanning the code