ENG

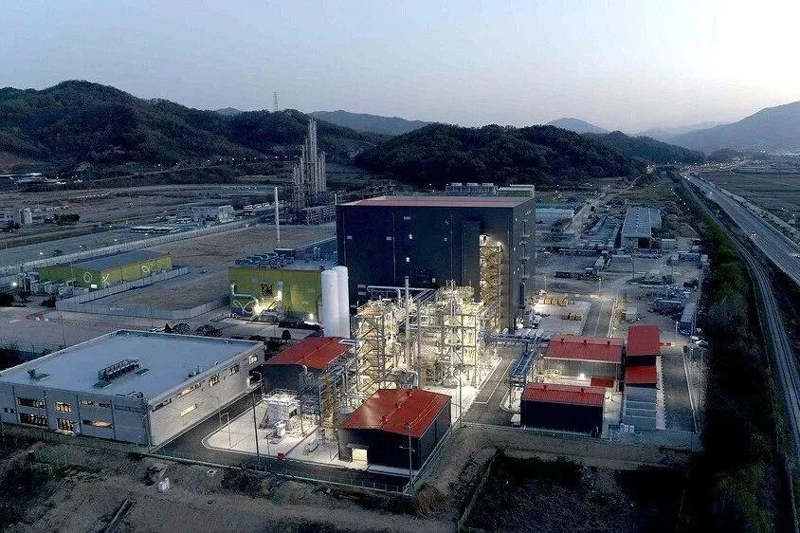

South Korea is reportedly on the verge of its first mass production project of silicon-based anode materials for electric vehicle batteries. The project is expected to begin commercial operations in early 2024, with an initial capacity of 2,000 tons per year to meet the manufacturing needs of 10GWh batteries.

This project is a joint venture between Group14 (USA) and SK Group (Korea). Using Group14's proprietary vapor deposition (CVD) technology route, the project will produce a silicon-carbon composite anode material called SCC55™ (carbon to silicon ratio of 55:45), which has five times the battery capacity of graphite anode materials while offering up to 50 percent higher energy density compared to traditional graphite.

In short, the production process of silicon-carbon negative electrodes begins with the carbonization of petrochemicals by polymerizing them to remove hydrogen, oxygen, and nitrogen. This is then pulverized and mixed with a silane material, and ultimately the silicon is deposited in the pores of the carbon support material.

Group14, whose investors include Porsche, ATL, Lightstone, BASF (BASF), SK Global, Microsoft, and the US Carbon Neutral Fund, is currently valued at more than $3 billion. Although the only public client is Porsche, it has been approached to liaise with major companies such as Mercedes-Benz and Airbus.

Group14 was founded in 2015, and according to public sources, SCC55™ is currently undergoing capacity expansion. At the startup plant in Washington, D.C., capacity has reached 120 tons per year; the South Korean plant, a joint venture with SK, has a capacity of 2,000 tons per year. In addition, there are two modular plants in Washington with a total capacity of 4,000 tons per year, which are expected to come on line in 2024.Group14 plans to continue to invest in 2,000 tons/year modular plants over the next ten years to support industries that are more difficult to electrify, such as aircraft and trucks.