ENG

★Welcome to explore the website:www.hanghangcha.com

Solid-state battery commercial process is expected to accelerate the overall acceleration of silicon-carbon anode dosage of high increase.

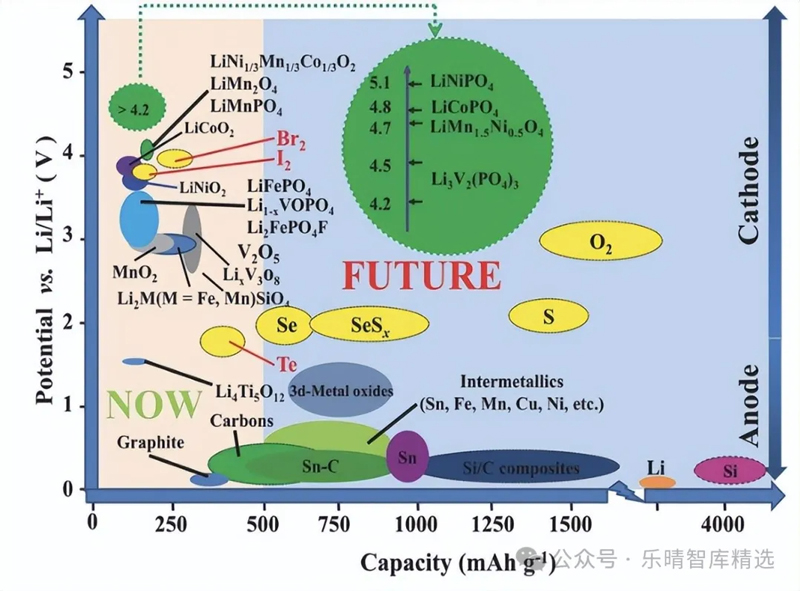

At present, the commercialized lithium-ion battery mainly adopts graphite as anode material, and its theoretical specific capacity is 372mAh/g, and its energy density enhancement has encountered a bottleneck, while the theoretical specific capacity of silicon-based materials is as high as 4200mAh/g, far exceeding that of graphite.

Silicon-based materials, with its high theoretical specific capacity and “high capacity + high operating voltage + low cost” advantages, has a wide range of prospects for use, and is currently regarded as a new generation of lithium anode materials, the application of solid-state batteries has attracted much attention.

The current high silicon carbon is the future development trend of negative electrode:

Source: Publicly available

01

Silicon-Carbon Anode Industry Overview

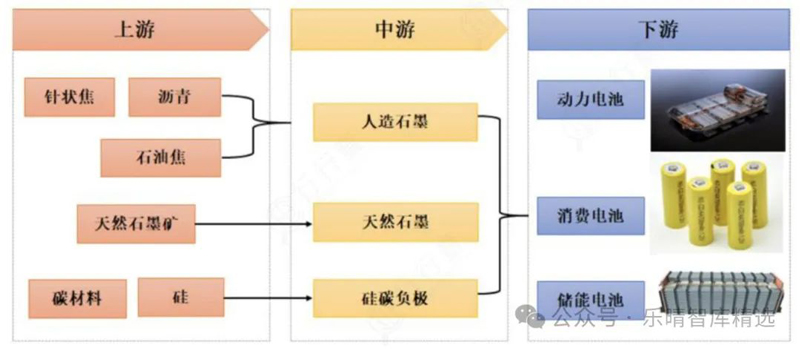

The upstream materials of lithium anode materials include petroleum coke, needle coke, asphalt coke and other chemical products and primary graphite and other raw materials; the midstream is the manufacturing process of anode materials; and the downstream is mainly in the application fields of power batteries, consumer batteries and industrial energy storage batteries.

Lithium anode industry chain diagram:

Artificial graphite and natural graphite are currently the most commonly used anode materials in lithium batteries, but their gram capacity has reached the upper limit, the current market demand for silicon-based materials is very clear.

Silicon-based materials include silicon-carbon and silicon-oxygen, etc., which not only have large reserves, low cost and no pollution, but also have a much higher theoretical specific capacity than that of carbon-based materials to reach 994mA-h/g.

Silicon-based materials, silicon-carbon anode is the key way to improve battery efficiency, can significantly improve the energy density of the battery, but also has a high degree of safety and rich reserves. In addition, silicon-carbon materials have superior fast-charging performance, with a structure that provides channels for lithium ions to embed from multiple directions, thus realizing efficient fast-charging to improve performance.

Silicon-based anode materials were first invented by Hitachi Chemical in 1996, and after Panasonic introduced batteries containing silicon in 2012, silicon-carbon anodes and silicon-oxygen anodes were industrialized in 2013 and 2014, respectively.

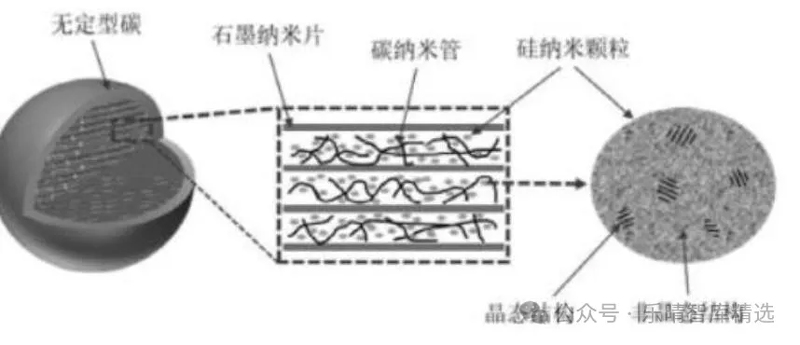

Silicon-carbon anodes are made by mixing nanosilicon and carbon materials. Nanosilicon materials are more effective in buffering the stress and deformation of silicon during the embedding and dislodging of lithium ions due to their smaller particle size and more voids. And the nanoparticles can shorten the diffusion distance of lithium ions, thus enhancing the lithium storage capacity of silicon materials.

Carbon not only functions as a buffer and conductor, but also provides channels for lithium ion transport, thus improving the Coulombic efficiency of the composite material.

Silicon-based anode materials are usually used by doping them into graphite anodes at a certain percentage (5%-10%). Since there are differences in the type, process and proportion of graphite doped by different silicon-based anode manufacturers, the performance of the products may vary.

Currently, silicon-carbon negative electrode products on the market are divided into two main categories: silicon nanopowder before impurity and finished silicon-carbon negative electrodes that have been doped.

In the preparation of silicon-carbon composite anode materials, a variety of methods can be used, such as chemical vapor deposition (CVD) method, mechanical ball milling method, spray method, magnesium thermal reduction method, sol-gel method and so on. Among them, the CVD method and mechanical ball milling method, which are simple and less costly, are more suitable for industrialized production.

Silicon-carbon negative electrode preparation diagram:

资料来源:X技术、粉体圈

Porous carbon and silane gas are the two core raw materials that make up the silicon-carbon anode.

Porous carbon plays an important role in the final performance of SiC negative electrode. Porous carbon is a new and innovative material that is highly compatible with silicon carbon anode, and its quality is crucial to the production of high-quality silicon carbon anode. New technology routes that utilize porous carbon structure are expected to drive the growth of the industry.

The quality of the carbon skeleton has a direct impact on the mass production capability of the product. In order to ensure the outstanding performance of the core, it is necessary to select the appropriate graphite to match different porous carbon. In different application scenarios, there are different requirements for the pore size, pore volume and porosity of the carbon skeleton, which leads to significant differences in performance, and thus the development process requires close cooperation with core design experts.

Representative companies of porous carbon layout include Group 14 in foreign countries and Lanxi Zhide in China.

In terms of silane gas, another major raw material, its usage is also expected to grow with the increase in downstream demand for silicon-carbon negative electrodes, with agencies estimating that the demand for silane gas will reach 17,053 tons by 2025.

The competitive landscape of the silane gas market is relatively centralized, mainly dominated by a few existing companies, with major suppliers including Silane Technology, Xingyang Technology, Zhongning Silicon Industry and other companies. Meanwhile, if comprehensive gas enterprises such as He Yuan Gas can successfully enter the industry, they will also occupy a place in the future market competition.

02

Silicon-Carbon Anode Market Landscape

Currently, the commercialization and application process of silicon-carbon composite anode materials has been fully accelerated. since 2021, leading companies such as Tesla and Ningde Times have started small-scale mass production of power battery products using silicon-carbon anode.

At present, there are not many domestic manufacturers in the main layout of silicon-based anode, mainly Ningde Times, Sugo Corporation, Betray, Jiangxi Zichen (a wholly-owned subsidiary of PuTaiLai), Tianmu Pilot, XiangFengHua, KaiJin Energy, ZhongKe Electric, Hunan XingCheng, and a few other companies. Foreign Japan's Shin-Etsu, Hitachi Chemical, Mitsubishi Chemical and South Korea GS Group and the United States Enevate and other companies also have a layout.

From the technical point of view, Betray started the research of silicon carbon negative electrode technology as early as 2006 and obtained the first relevant invention patent; the core technology of high-end nano-silicon carbon negative electrode material of Tianmu Pilot is the world's first by the Institute of Physics of the Chinese Academy of Sciences, which has been successfully industrialized. In addition, manufacturers such as Weilan New Energy, Ganfeng Lithium and Shanghai Washba also have layouts in silicon carbon anode materials.

Overall, the concentration of anode material manufacturers in China is relatively high, and the certification cycle of downstream anode material manufacturers for capping materials is usually between 6-12 months, and there are high requirements for suppliers' capacity scale, supply assurance ability and batch stability. Therefore, the leading manufacturers who are the first to enter the market have obvious first-mover advantages, and the future market pattern is expected to further concentrate on the head.

Solid-state battery system can effectively inhibit the defects of silicon negative electrode, high ionic conductivity electrolyte in the sulfide system can promote the diffusion of ions in the silicon negative electrode, and thus the application of silicon negative electrode in solid-state batteries is expected to further expand.

The 100 Industry Chain Atlas, which takes you through the industry.

↑↑↑Click on the image above to view the study